Carpenter Oak had the privilege to receive a visit from members of the Royal Forestry Society. The Royal Forestry Society (RFS) is an educational charity inspiring excellence and passion in woodland management. They are the largest and longest established education charity promoting the wise management of woods in England, Wales and Northern Ireland.

Interested in the role that trees and woodlands play in the landscape, economy and culture of our country they were keen to hear how Carpenter Oak source their sustainable timber. Of particular interest was a tour of our workshops, a visit to our Show Barn and the story of one of our frequently used sawmills.

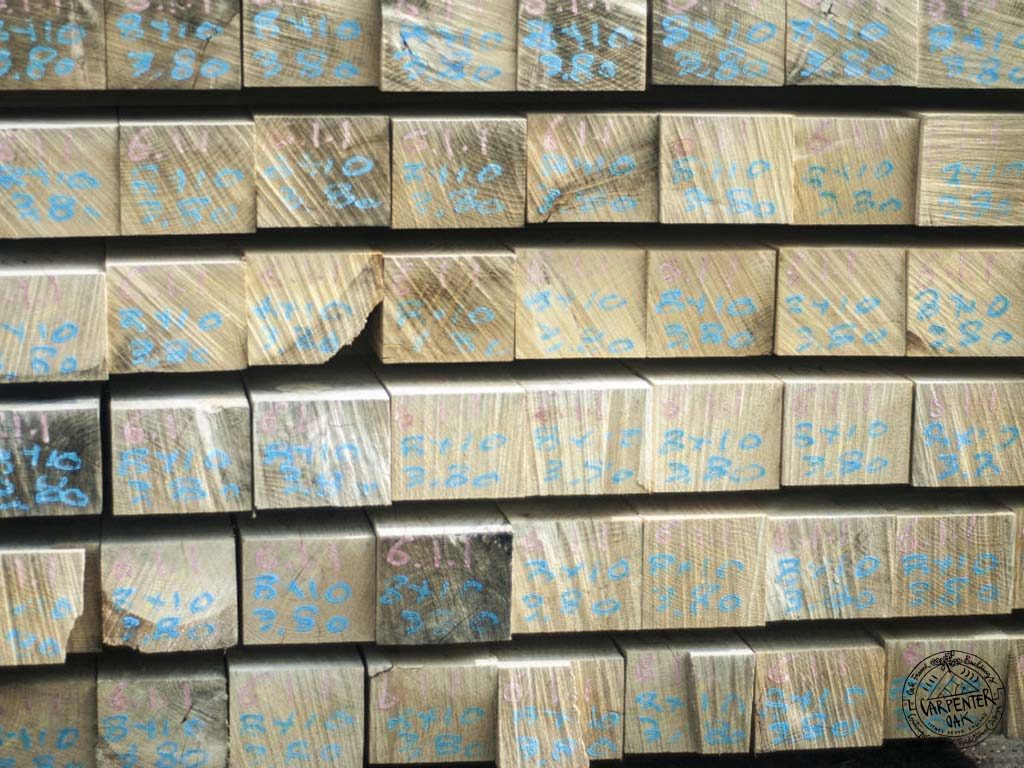

The RFS were given a tour of our Devon yard by director Paul Kirkup, who introduced them to some of our current projects. Carpenters on hand were able to give a true insight to the craftsmanship and techniques used in our timber framing. With the timber being of specific importance to the RFS, some time was spent looking at our stacked timber whilst discussing soil typography and timber variations.

Moving into the Show Barn, Paul outlined some of the specifics of the building. The 3 bay barn is a 1 ½ story building designed to give a sense of what can be achieved in a full build. It contains elements that you would expect to see in a full sized home. RFS members learnt about the SIPs panelling methods used to insulate many modern timber frame buildings and were able to view our demonstration model. Through the use of Structural Insulated Panels (SIPs) panels our Show Barn achieves a high level of air tightness and energy efficiency.

- Show Barn interior with mezzanine within a green oak frame in Cornworthy, Devon.

- Image courtesy of Kim Sayer

The 10 year old frame evidences shrinking that occurs as green oak frames dry out. The characteristics of the wood are clear to see, as are the methods used to join the frame together. Cracking and twisting of the wood that occurs overtime can be appreciated alongside methods used to minimise this. Inconveniences of water-staining are visible as is the simple approach of steam cleaning used to resolve this. The advantage of visiting the Show Barn is that people are able to experience the living qualities that wood continues to have when used as a timber frame whilst learning about our materials and techniques.

- Splitting

- Knots

- Shrinkage

Carpenter Oak work hard to use sustainably resourced timber. In 2013, Paul visited one of our frequently used sawmills in France and was keen to share his experience with the RFS. The family owned mill is a small business that employees 8 people. The timber is predominately sourced within 100km of the sawmill. The woods generally contain a mixture of oak, beech and hornbeam. The species that Carpenter Oak work with are Quercus Robur and Quercus Petraea and all the hybrids that happen in between.

Soil variation plays a big part in timber variations, the sawmill owner knows which areas produce timbers appropriate for specific uses. For example, certain areas grow timber that is perfect for barrel making. This information has been passed down through generations, something that the UK industry has perhaps lost over time.

The forest is approximately divided 50/50 between private and public ownership. The National Forests Office (ONF) is the French equivalent to the Forestry Commission who manage the public forests in a time honoured tradition, viewed as second to none.

The process involves winter felling, beech is sold on whilst the oak is kept and sawn at the mill. The timber is used for barrel making, flooring and our timber frames. The timber is all of a similar size and between 90 and 120 years old. The logs are elected and timber sizes marked up before being cut to length. Once cut, they go on to the de-barking machine before being sawn to size. The timber quality is then checked and coded for Carpenter Oak.

Also at the sawmill are some exceptionally large timbers, of up to 10m in length that are used by local timber framers. French framers work in a traditional way using almost a whole tree for a floor beam, the detailing not dissimilar from medieval times.

Paul also visited the woodlands which appear chaotic at first but became much more ordered when explained. On entering the wood the sawmill owner has a list of trees he needs. He has to search the woodland for appropriate trees, mark them and work out what he is willing to bid for them. He has to assess the timber quality by sight, what is inside the tree is hidden, so much knowledge and skill is needed when assessing trees.

The ONF go through the woodland marking the trees that need to be felled before buyers are able to choose trees. They plan to leave trees on a 10m grid to allow regeneration of the woodland. All of the woodland is of natural regeneration, no planting is needed. Exceptional trees will be left, creating beautiful places to wonder around. The understory can be quite thick on the ground, with a carpet of oak saplings. The Hornbeam is of particular high value so is well looked after.

French woodlands experience a 1.5% increase, in area of oak, per year with a use of 0.5%- 0.75% usage year. This means that there is an ever-growing increase year on year.

As well as supporting the forestry trade in Europe, we invest in planting schemes throughout the UK by working with and supporting the Woodland Trust – the UK’s largest woodland conservation charity. As well as planting trees and restoring ancient forests, their work also involves protecting and campaigning on behalf of UK woodland.

If you are interested in becoming a member or volunteering for the RFS they would be happy to hear from you.

If you have a project in mind and would like to tour our yard and visit one of our show homes, please contact us.

Alongside oak frames, Carpenter Oak produce frames made with Douglas fir, larch and glulam

To watch some of the process from mill to frame, view our Timeless Film